A Complete Guide to Oil Pumps for Racing Engines

Racing enthusiasts understand how vital every part of an engine is when performing in a race. While oil pumps may not receive as much attention as turbochargers or exhaust systems, they are equally vital for ensuring a smoothly running engine. This complete guide to oil pumps for racing engines provides essential information for making informed decisions regarding high-performance vehicles.

Types of Oil Pumps

There are many different types of oil pumps. Let’s cover a few common ones that you’re likely to come across.

Gear Pump

Gear pumps are one of the most popular options among racers for reliability and efficiency. They consist of two gears—the drive gear attached to the crankshaft and the driven gear—that move oil from the sump to the engine components. Their design minimizes leaks and ensures steady oil pressure, even at high speeds.

Rotor Pump

With a rotor inside an outer ring, rotor pumps deliver smooth and efficient oil flow. They are often in production vehicles, but many racers prefer this design because it handles high volumes of oil without sacrificing pressure.

Vane Pump

Known for their compact size and versatility, vane pumps use retractable sheets that slide in and out of a rotor to move oil. While they are less common in racing engines, some drivers choose them for specific applications, particularly when space is limited.

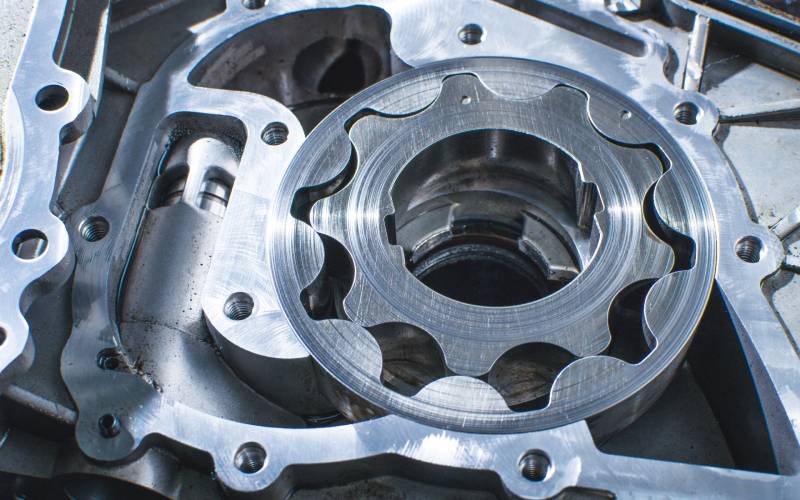

Gerotor Pump

The gerotor pump combines aspects of gear and rotor pumps, using a rotor within a larger gear ring. This pump’s popularity stems from its ability to produce consistent oil flow even at low RPMs, making it a great option for racers looking for reliability across varying speeds.

Dry Sump Pump

Perhaps the most advanced option, dry sump pumps circulate oil from a separate reservoir rather than the oil pan. This design offers several advantages, including reduced engine drag, improved oil cooling, and increased capacity for high-performance applications. Though expensive, many professional racers choose dry sump systems to deliver unbeatable oil during races.

Choosing the Right Oil Pump for My Race Car

Selecting the optimal oil pump for your race car requires a nuanced understanding of the vehicle’s specific demands and each pump type’s technical attributes. Here are some helpful approaches to guide you to the right decision.

1. Analyze Engine Specifications

The first step is thoroughly understanding your engine’s specifications, including size, RPM range, and power output. To try and put it into perspective: a high-performance engine elevating higher RPMs, for instance, demand pumps that can sustain higher oil flow rates to maintain lubrication under intense conditions.

2. Evaluate Environmental Conditions

Racers always need to consider the typical racing conditions that they’re likely to face. There’s a huge difference between short burst races versus prolonged endurance races. Each scenario demands a different approach. High-temperature environments might benefit from a dry sump system due to its superior cooling capabilities, while gear pumps optimize better in colder conditions because of pressure maintenance.

3. Determine Space and Layout Constraints

The first way to determine space and layout constraints is to evaluate the available space. This part is something to always do in the engine compartment, and it’s an important step when fitting an oil pump. Some oil pumps are compact enough for tight setups, but more extensive systems, like dry sumps, need more space for the reservoir and more complex plumbing.

4. Consider Maintenance and Budget

Cost considerations and future maintenance play critical roles in my decision. Gear pumps are typically low-maintenance and offer a reliable balance between performance and cost, making them great for racers. However, investing in a dry sump pump may provide long-term value in professional racing contexts if racers have a higher budget and are looking for distinct performance.

5. Analyze Oil Viscosity and Pump Compatibility

Different oils have varying viscosities, so it’s always a good idea to ensure that the chosen oil pump operates seamlessly with the chosen oil type. Optimal oil viscosity can significantly affect pump efficiency, contributing to both performance and engine longevity.

Difference Between Regular and Professional Racing Oil Pumps

When comparing oil pumps in standard consumer vehicles to those in professional racing, several key differences emerge, primarily driven by performance needs and environmental demands. An oil pump in production cars suits everyday engine operations at moderate RPMs and typical driving conditions. These pumps emphasize durability and low maintenance, operating efficiently within mass manufacturing costs.

In contrast, a race car oil pump reaches peak performance under extreme conditions. Advanced systems like dry sump pumps can handle the high stress and elevated temperatures while racing. These pumps maximize oil delivery and maintain precise oil pressure across a wide RPM range, ensuring consistent lubrication even in demanding situations. Racing pumps often use lightweight materials and complex designs to reduce engine drag and improve cooling. This specialized engineering assists in withstanding challenging race tracks.

Installation Tips From Industry Pros

After narrowing down your choices, it’s time to focus on installation. Following these pro tips will ease you into the process.

Thoroughly Clean All Components

Any debris or dirt can lead to premature pump failure, which is costly and inconvenient. You always want to make sure that every part, including the pump housing, fittings, and connectors, is spotless before starting the installation process. Taking the time to clean ensures it seals better and maintains component longevity.

Use Quality Gaskets and Seals

Some racers may try to save money upfront by choosing cost-effective parts, but it often results in leaks and pressure loss down the line. You should always invest in high-grade gaskets and seals to keep them fitting right and maintain system integrity. Ultimately, investing in gaskets and seals produced from high-quality materials saves money on engine repairs later.

Double-Check Clearances

Incorrect clearances can lead to diminished performance and even catastrophic engine damage. Take the time to make sure that all clearances fall within the manufacturer’s specifications to ensure optimal engine function. This step is vital for the longevity and efficiency of your engine, as it allows for proper fluid dynamics.

An Oil Pump Saves the Day

Oil pumps might not have the glamor of a new turbo, but they are a linchpin in racing engine performance. If you’re looking to make a savvy choice that can help you win the race, choosing the right oil pump can make a huge difference when you’re on the track.

Make the Drive Better With Driven Racing Oil

Turn to Driven Racing Oil for all the expert advice you need when it comes to your engine’s oil. Their experience goes beyond knowing make and model specifications; they also educate and recommend the best products for race car owners and mechanics. They’re the go-to source for information on the best type of oil for a racing vehicle. With their guidance, you can feel confident in selecting the optimal race engine oil tailored to your vehicle’s needs. Be the best driver on the track and switch to Driven Racing Oil.

You must login to post comments.