One of the main things that enthusiasts love about racing is the speed and power of the race car. Those who really invest in the hobby marvel at race cars but may not understand the intricate engineering that allows these machines to perform at such a high level.

Knowing what goes into a racing engine is a big part of race car design. These machines often push the limits of physics and engineering. Engineers must consider precision, durability, innovation, horsepower, and other factors. Driven Racing Oil will explain what makes these cars so special and why enthusiasts get such a kick out of them.

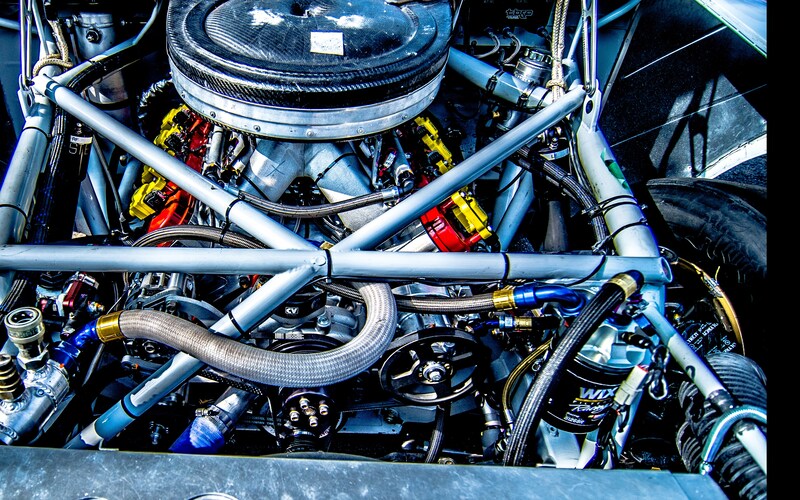

The Foundation of a Racing Engine

A robust foundation is the first part of every racing engine. The main block serves as the core structure that houses the cylinders, pistons, crankshaft, and other key components. Unlike standard car engines, engineers construct engine blocks from lightweight yet extremely durable materials, such as aluminum alloys, to ensure the engine block doesn’t weigh the car down.

The design of the engine block is another critical factor. Engineers need blocks to withstand extreme temperatures and the immense pressure that comes from racing. It also needs to accommodate advanced cooling systems to regulate temperature. Even the most advanced racing engines can fail under the rigorous demands of competitive racing without a solid and reliable foundation.

Maximizing Airflow With Cylinder Heads

The cylinder head is pivotal for determining how well a racing engine performs. It contains the intake and exhaust ports, which control the flow of air and fuel into the engine and the release of exhaust gases. These ports impact engine efficiency and power output.

Racing engines rely on specific cylinder heads that maximize airflow. Engineers use computer simulations and advanced techniques, such as CFD (Computational Fluid Dynamics), to design ports with minimal resistance. Certain race car engines utilize multi-valve cylinder heads that allow more air into the combustion chamber to maximize power delivery.

The Role of Pistons in Power Generation

Pistons convert fuel into power, making them a fundamental part of any racing engine. They move with the cylinders and move with the combustion of air-fuel mixtures. Unlike everyday passenger cars, racing cars need high-strength aluminum pistons to endure the immense heat and pressure that race cars experience.

Even the smallest imperfection can compromise performance or lead to catastrophic engine failure. Engineers carefully design pistons to minimize weight while maximizing strength, ensuring that they can move rapidly without bending or breaking.

Crankshaft and Connecting Rod Dynamics

The crankshaft and connecting rods are the mechanical links between the pistons and the wheels. Combustion generates energy and transfers from the pistons to the crankshaft, converting this motion into rotational force. That force is what drives vehicles forward.

Racing engines need strong but lightweight crankshafts. The design minimizes the risk of bending and resonance while the race car is running. Meanwhile, engineers make connecting rods for strength and precision, using forged steel or titanium to handle the stress of rapid spinning.

Advanced Fuel Injection Systems

Considering the fuel injection systems is important when looking into race car design to see what goes into a racing engine. This system controls the amount of fuel that goes into the engine for combustion. This system relies heavily on precision since an imbalanced air-fuel ratio can undermine performance or even damage the engine. Modern racing engines often use direct fuel injection for better accuracy compared to port fuel injection.

Direct fuel injection sprays fuel directly into the combustion chamber, allowing for more precise control of timing and quantity. Engineers use advanced software to fine-tune the system and optimize performances during races. High-performance injections and fuel pumps work to handle the increased demand for racing engines over most traditional vehicles.

Revolutionizing Air Intake Systems

The air intake system is incredibly important to any racing engine since air is a key component of combustion. These systems supply clean, cool air to the engine, which can greatly enhance performance. Engineers specifically design special intake systems to minimize resistance and increase airflow. Specialized intake systems minimize resistance and maximize airflow.

Racing cars often feature ram-air intake systems that force cool air into the engine while the car is in motion. This system improves power output and manages internal temperatures. Some systems use special filters that maintain airflow and remove any debris that could damage the engine.

Precision Timing With Camshafts

The camshaft controls the operation of the engine’s intake and exhaust valves. Timing is everything since even fractions of a second can make a big difference when it comes to racing. The camshaft creates perfect timing for the valves to open and maximize airflow and combustion.

Racing engines often use custom, more aggressive camshafts that increase valve lift and duration. These custom camshafts allow for greater amounts of air and fuel to enter the combustion chamber, boosting power. Double-overhead camshaft (DOHC) configurations are also common in racing engines, as they allow for more precise control of valve timing.

Cooling Systems for Extreme Conditions

Racing engines operate under extreme conditions, naturally leading to extreme heat. Engines need effective cooling systems to prevent overheating while maintaining durability during a race. These systems often feature high-capacity radiators, water pumps, and advanced thermal management techniques.

Some racing engines use special coolant mixtures that improve heat transfer and protect against high temperatures. Another important component is how air flows through the radiator to try and get the air to the cooling system without causing problems with the car’s performance.

Exhaust Systems Designed for Performance

Customized exhaust systems minimize emissions while enhancing engine performance. The primary job of the exhaust is removing spent fuels, allowing fresh air and usable fuel to run through it.

Racing exhaust systems frequently use lightweight materials and feature headers to try and reduce back pressure. Some systems include catalytic converters for racing applications, meeting regulatory requirements without sacrificing performance.

The Power of Software and Data Analysis

Modern racing engines utilize software and hardware. Advanced Engine Control Units (ECUs) monitor and manage nearly every aspect of the engine’s operation, from fuel injection and ignition timing to valve control and temperature regulation.

Racing teams use the data they get from these systems to try and improve engine performance before and even during races. Engines feature a range of sensors to send real-time data to the ECU, allowing the team to adjust parameters. These systems help engineers maximize performance and ensure reliability from their race cars.

Consider Driven Racing Oil for those passionate about protecting and enhancing the performance of your racing engine. Our break-in motor oil and specialized products to get your engine going can optimize your engine’s durability and efficiency. Give your engine the care it deserves with solutions engineered for peak performance and reliability—choose Driven Racing Oil today.